Inexpensive, flexible and versatile.

The ILP-4200 is a compact color label printer with an optional cutter or peeler version. This allows you to process the cut or peeled label directly, saving time and unnecessary process steps. The versatility of this printer makes it ideal for use in production, logistics, automation and wherever high-quality color labels need to be printed on-demand – from a single label to a full roll.

Depending on the application and label materials to be printed, you can switch flexibly between large, low-cost pigment and dye ink cartridges.

Simple and intuitive control and operation of the printer is possible via the display and the supplied software. The USB, Ethernet and 24V PLC interface mean that the printer can be used in a wide variety of environments – from desktop devices to automation.

The ILP-4200 combines versatility, reliability and performance in a cost-effective package.

ILP-4200 product brochure

You can download the product brochure for the ILP-4200 here.

Clogged print head? Was yesterday.

The print head can be replaced by the user without prior knowledge within seconds if the print head is defective / dried out or if the type of ink used simply needs to be changed.

If the printer is not in use for a longer period of time, the print head can be removed and sealed airtight. This saves time and money because the print head does not have to clean itself regularly and there is no risk of it drying out. When the printer is needed again, simply switch it on, insert the print head and ink cartridge and the printer is ready to go again.

Professional print results.

Ideal for small to medium print volumes. No more large minimum order quantities in print shops. Quickly create and print various labels. Personalized labels on demand for your customers. With a print width of up to 210 mm, a print speed of up to 130 mm per second and a print resolution of 1200 x 1200 dpi, you can achieve professional print results.

Thanks to the large ink cartridges, larger print volumes can also be handled. The free-moving sensor enables printing on numerous label formats.

Cleaning and maintenance

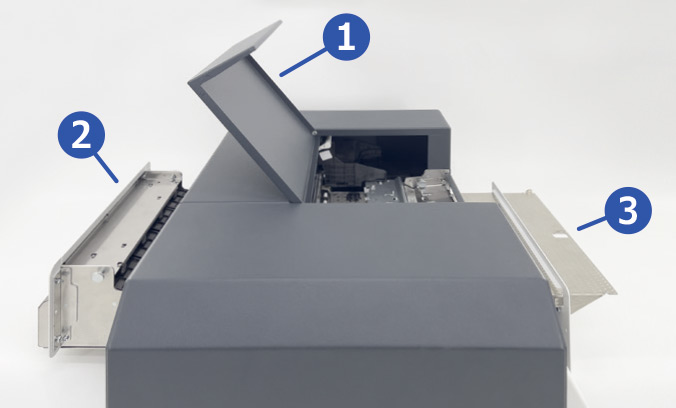

If a label does get caught, it can be reached quickly via 3 access routes (see illustration above) thanks to the modular, accessible design. This also makes cleaning and maintenance easier.

Compact and durable

For industrial use, the printer is protected by a powder-coated metal housing that complies with increased safety regulations.

Recyclable metal was used for the majority of the printer’s components. This means that all individual parts are durable and replaceable.

Our promise

We always have a personal contact person available in sales and service. We offer comprehensive service and warranty packages so that there are no long interruptions during maintenance or repairs.

We can also come to your premises on request.

Directly to the webshop

Click on the button now and enjoy shopping in the KOMDRUCK webshop – conveniently, quickly and securely!

New user interface.

The ILP-4200 can be operated and controlled easily and intuitively via the new ILP hub. You will find all information from the ink level to the IP address in a clearly arranged application. In addition, all of the printer’s functions can be easily controlled from here: from setting up the labels to the margin settings.

Fast and automatic label setup.

The latest generation of the ILP automatically feeds the labels when they are applied and calculates the label dimensions all by itself thanks to innovative sensor technology. You are ready to go straight away, without having to set up or enter the label dimensions manually. The ILP supports all media types from die-cut (gap) to Z-fold and can accurately detect a wide range of label sizes, materials and shapes thanks to adjustable sensors – even different labels on the same roll.

New user interface.

The ILP-4200 can be operated and controlled easily and intuitively via the new ILP hub. You will find all information from the ink level to the IP address in a clearly arranged application. In addition, all of the printer’s functions can be easily controlled from here: from setting up the labels to the margin settings.

Fast and automatic label setup.

The latest generation of the ILP automatically feeds the labels when they are applied and calculates the label dimensions all by itself thanks to innovative sensor technology. You are ready to go straight away, without having to set up or enter the label dimensions manually. The ILP supports all media types from die-cut (gap) to Z-fold and can accurately detect a wide range of label sizes, materials and shapes thanks to adjustable sensors – even different labels on the same roll.

Three special inks for all requirements and label materials

Different requirements and label materials from matt paper to high-gloss polyethylene require different types of ink for smear-free results in good quality. We have developed 3 types of ink for the ILP-4200 for the first time:

Dye ink

For particularly color-intensive, uniform and high-contrast labels in photo-graphic printing (dye-based ink).

Pigmented ink

For particularly long-lasting, infrared-readable, waterproof and UV-resistant applications on porous label material (paper).

Innovation: “Nanoblack”

Unique on the market: Has the properties of a pigmented ink and dries into high-gloss labels faster than any other ink.

Areas of application.

The printer is versatile, not least thanks to its various interfaces. As a desktop device via USB or LAN or in an automation system with an applicator via the 24V PLC controller.

This also enables the connection of customized peripheral devices, such as a foot pedal to control the cutting / dispensing mechanism.

Technical data.

| Category: | Desktop full color label printer |

| Printing process: | Thermal inkjet printing |

| Print speed: | Up to 13.2 cm/s in standard mode |

| Print quality: | Max. 1200 x 1200 dpi |

| Print width: | Max. 210 mm |

| Print length: | Max. 1219,2 mm |

| Ink: | Water-based, solvent-free special ink (CMYK): K (Dye / Pigment / Nanopigment) – 78ml CMY (Dye / Pigment) – 26ml |

| Print head: | Replaceable, Unfilled (Empty) |

| Label feeding / detection: | Sensor-monitored label feed with automatic feed (Auto-Feed) and label detection (Auto-Teach) |

| Label sensors: | Movable light sensor for contour-cut labels (Gap) Reflective sensor for marking strips (Blackmark) |

| Supported label types: | Die-cut label (Die-Cut / Gap) Label with black markings (Blackmark) Continuous label (Continuous) Continuous paper (Z-Fold) Papersheet (A4) |

| Printer models: | Standard with manual tear-off edge Cutter with automatic label cutting function (circular blade) Peeler with integrated label dispensing function |

| Interfaces and network connection: | USB 2.0 / LAN (Ethernet) / 24V PLC control |

| Supported operating systems: | Windows® 11, 10, 8.1, 8, 7 |

| External power supply: | 100 – 240 V alternating current / frequency: 50 – 60 Hz |

| Memory (RAM): | 32 MB |

| Weight: | approx. 15 kg |

| Dimension: | 207 x 486 x 330 (H x W x D mm) |

| Service: | 12 months manufacturer’s warranty 24, 36, 48 or 60 months bring-in warranty extension Includes personal contact person in the manufacturer’s direct sales department, |